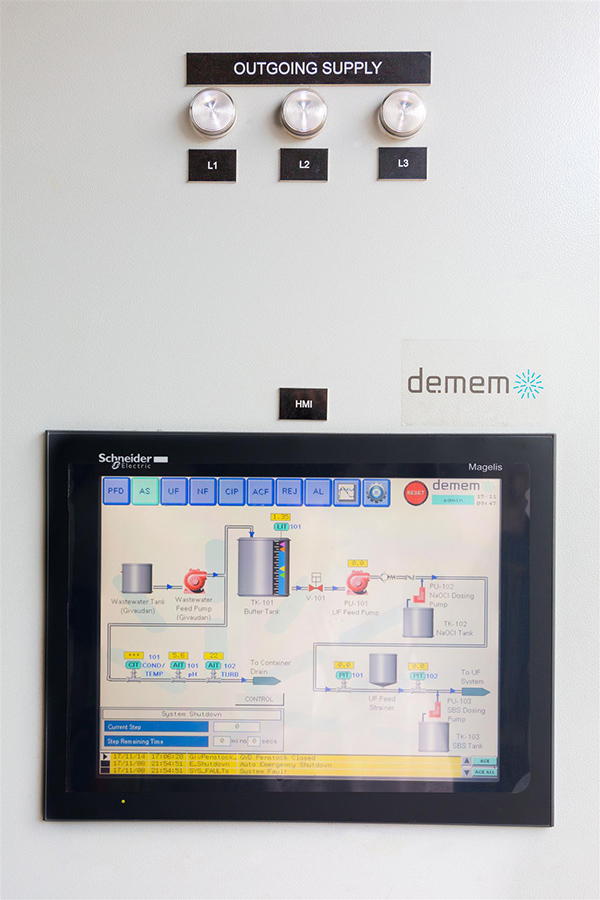

Mission-Critical Services for a Clean Environment

De.mem Limited (ASX:DEM) is an Australian headquartered business that provides solutions for de-centralized, on-site water and waste water treatment to industrial clients, based on our range of proprietary hollow fibre membrane technology.

We help our clients to clean and reuse water, while meeting regulatory objectives and reducing cost.